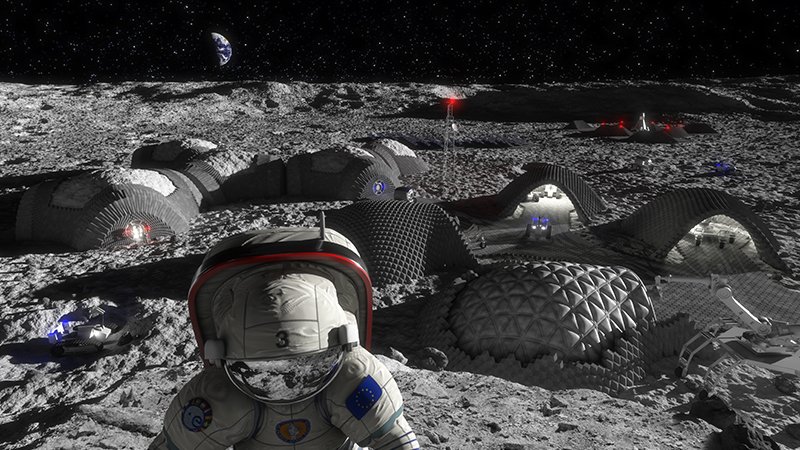

Image courtesy European Space Agency.

The ESA’s Discovery Program has spent the last two decades studying the viability of off-Earth manufacturing and its use in future space exploration.

The concept hardly needs much explanation: it involves manufacturing things on a planetary body other than Earth.

While the basic idea is simple, the execution is, of course, far more complicated.

Let us look at what the ESA knows and how it could help with missions to the Moon and Mars.

Missions to Mars, for now, will require a stop-off on the Moon.

We will need a lunar station for refuelling and other purposes.

There must also be infrastructure on Mars to support life and colonisation later down the line.

Transporting this infrastructure from Earth would be expensive, almost prohibitively so.

Consider everything humans would need to stay alive on another planet and the size of the spacecraft needed to move it around.

Off-Earth manufacturing offers a solution by reducing the number of raw materials required.

In theory, off-Earth manufacturing could produce everything from communications equipment to energy production and storage devices.

It could also produce enough food and water to support communities and eventually create propellants for returning to Earth.

Considering these are essential aspects of colonising other planets, it has excellent potential.

Off-Earth manufacturing relies on the premise of in-situ resource utilisation (ISRU) – using local materials to build infrastructure and amenities.

ISRU would utilise 3D printing to convert local materials into usable products.

One study investigated the suitability of lunar soil for 3D printing building blocks, while another tested the potential of the lunar regolith for printing spare parts and equipment.

Unsurprisingly, lunar dust would be a primary source of basically everything on the Moon.

In 2020, the ESA thoroughly tested this idea by designing and producing a plant that converts lunar dust into oxygen.

A helpful side effect was that it also produced metal alloys, and so the ESA is now studying their viability for 3D printing.

It hopes to test a sustainable plant on the Moon and plans to demonstrate the technology by the middle of this decade.

As it stands, the findings of these ISRU missions on the Moon could lead to Mars-based technology.

Refining the concepts on a closer celestial body would give us a practical knowledge base for moving to Mars.

NASA launched its MOXIE test mission on the Perseverance rover.

MOXIE stands for Mars Oxygen In-Situ Resource Utilization Experiment; its job is to produce oxygen from Mars’ CO2-rich atmosphere.

Image courtesy European Space Agency.

The ESA used its Open Space Innovation Platform for habitats, technology, and ISRU concepts.

The next step will be to test these and expand on the viability of off-Earth manufacturing.

As the ESA plans to return to the Moon in 2024, the next few years will likely produce some fascinating data about what this concept can do.